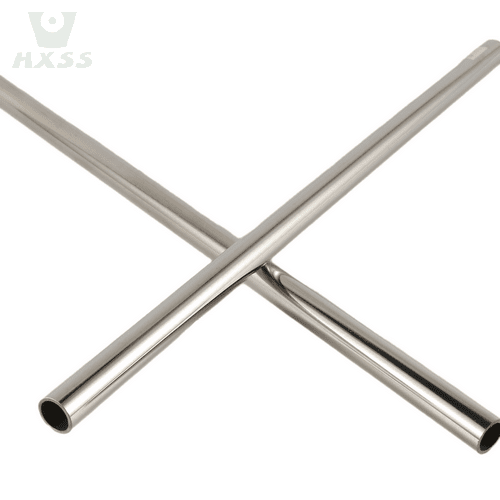

Welded steel pipes, also called welded pipes, are steel tubes made by welding steel or strip steel after crimping and forming. Generally, the length is 6 meters. It is divided into round welded pipe and special-shaped (square, flat, etc.) welded tube.

Stainless Steel Welded Tubes

Stainless Steel Welded Tubes Suppliers | Manufacturers | Exporters

Welded steel pipes, also called welded pipes, are steel tubes made by welding steel or strip steel after crimping and forming. Generally, the length is 6 meters. Welded steel pipes have a simple production process, high production efficiency, many varieties and specifications, and low equipment investment, but their general strength is lower than seamless steel pipes.

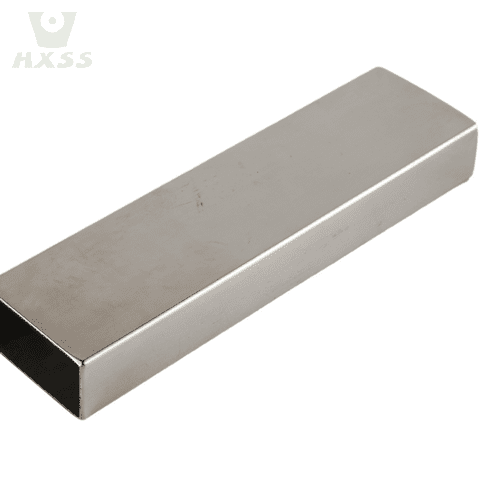

The blanks used for welded steel tubes are steel plates or strip steels, which are divided into furnace-welded pipes, electric resistance welded (resistance welded) pipes, and automatic arc stainless steel welded tubes due to their different welding processes. Because of its different welding forms, it can be divided into two types: straight seam welded pipe and spiral welded pipe. Because of its end shape, it is divided into a round welded pipe and a special-shaped (square, flat, etc.) welded tube.

Specifications of Stainless Steel Welded Pipe

Item | stainless steel welded tube(stainless steel welded pipe tube, welded steel pipe, stainless steel welded pipe, stainless tube welding) |

Grades | GB, AISI, ASTM, DIN, EN, SUS, UNS, etc Grade:304, SS 304, 304L, 316, 316L, 409, 2205, etc |

Stainless Steel Welded Tube OD | 0.188”–4.500” (4.78mm–104.3 mm) or as customers’ request |

| Stainless Steel Welded Tube Wall | 0.016” – 0.236” (0.406mm-0 5.994 mm) or as customers’ request |

| Size | 1 inch stainless steel tubing 12mm internal diameter steel tube |

| Manufacturer | Tisco steel, Posco steel, Bao steel, etc |

Shapes of Stainless Steel Welded Tube

Stainless Steel Welded Pipes Process

Stainless steel welded pipes polishing

Raw material uncoiling-leveling-end cutting and welding-looper-forming-welding-internal and external bead removal-pre-correction-induction heat treatment-sizing and straightening-eddy current testing-cutting off-water pressure inspection-pickling-final inspection (Strictly check)-packaging-shipping.

Application range of Stainless Steel Welded Tubes

Products are widely used in water supply engineering, the petrochemical industry, the chemical industry, the power industry, agricultural irrigation, and urban construction. It is one of the 20 key products developed in my country.

For liquid transportation: water supply and drainage. For gas transportation: coal gas, steam, liquefied petroleum gas.

For structural purposes: as piling pipes and bridges; pipes for docks, roads, and building structures.

The difference between stainless steel welded tubes and seamless pipe

- In terms of appearance, the difference between seamless steel pipe and welded steel pipe is that the inner wall of the welded pipe has welding ribs, while the seamless steel pipe does not.

- The pressure of the seamless pipe is higher, and the welded pipe is generally about 10 MPa. Now the welded pipe is seamlessly treated.

- Seamless steel pipes are formed in one step during rolling. Welded steel pipes need to be rolled and welded, usually spiral welding and direct welding. The performance of seamless pipe is better, and of course, the price is higher.

How to Weld Stainless Steel?

There is a kind of welding machine called an argon arc welding machine, which is connected by a bottle of argon gas with a tube, connected to a special welding gun, and then spot welding with a stainless steel electrode with a diameter of about 1.5mm. The place where argon gas is automatically released from the bottle to weld the ground on the screen so is called argon arc welding.