Stainless steel washing method according to surface condition

When washing, please be careful not to scratch the surface. Avoid using bleaching ingredients and detergents containing abrasives, steel balls (brush roller balls), abrasive tools,

Call Us Today! +86-13761906384

When washing, please be careful not to scratch the surface. Avoid using bleaching ingredients and detergents containing abrasives, steel balls (brush roller balls), abrasive tools,

1) After the stainless steel raw materials (stainless steel and carbon steel) are transported to the clad plate factory, a blank assembly is required during the production

Antibacterial Stainless Steel: a new material with both structural and functional characteristics In the production of kitchen equipment, medical equipment, bathroom supplies, and cleaning and

According to the regulations of GB4229-84, including stainless steel hot rolled steel plate and stainless steel cold-rolled steel sheet specified in the general calculation method for standard grades of

Stainless steel ‘mailboxes production after etching processing, chemical reactions, or physical impact is the material used and removing technology. Etching techniques can be divided into two categories,

Grinding stainless steel is a common process used in various industries, including manufacturing, construction, and metalworking. The primary purpose of grinding stainless steel is to

Q-Taixin 038-2008: Technical requirements for 301 series stainless steel plates (coils) for elastic componentsTechnical conditions of 301 series stainless steel plate (coil) for elastic elements

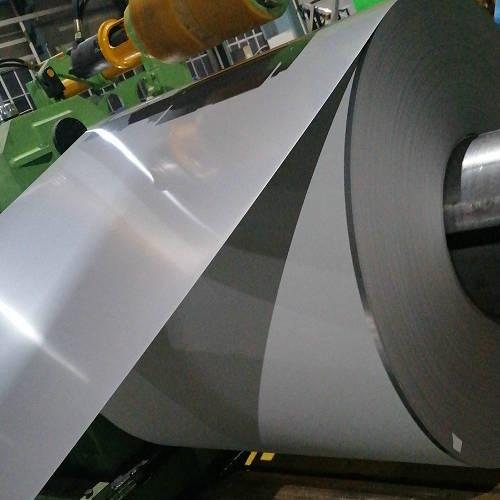

Corrosion Resistance of 316 Stainless Steel Coil 316 stainless steel coil corrosion resistance is superior to that of 304/304l stainless steel and it has good corrosion resistance

Common stainless steel smelting, forging and rolling Shrinkage cavity, shrinkage in the molten steel in the steel mold formation of shrinkage cavity, shrinkage cavity. Transverse crack: refers

Recently, my country’s exports of stainless steel products have encountered bottlenecks. In particular, food-grade stainless steel products related to food safety have been restricted by the food

Fill out the form below, and we will be in touch shortly.