Stainless Steel Perforated Plate(4mm-10mm)

There are many types and specifications of stainless steel perforated plates. The perforated plate has good hardness and will not be damaged after a period of time. In addition, the perforated plate is beautiful and generous. They are also used in many real-life applications, such as cement, environmental protection, decoration, etc. Life will not be polluted. The size and thickness of the perforated plate can be customized according to customer requirements.

Contents [hide]

Stainless Steel Perforated Plate Supplier | Manufacturer | Exporter

As a leading stainless steel perforated plate supplier, manufacturer, and exporter in China, we focus on providing high-quality stainless steel perforated plates for a wide range of industrial and architectural applications. The stainless steel perforated plates we provide meet your needs in terms of design and functionality with their excellent corrosion resistance and strength.

Whether you need stainless steel perforated plates for screening, decoration, or protection, we can provide a variety of specifications and aperture options to meet different application requirements. Our products not only have competitive stainless steel perforated plate prices but also guarantee high-quality manufacturing processes and durability.

Please contact us directly to learn about the latest stainless steel perforated plate prices and get professional quotes and solutions.

Stainless Steel Perforated Plate Supplier | Manufacturer | Exporter

As a leading stainless steel perforated plate supplier, manufacturer, and exporter in China, we focus on providing high-quality stainless steel perforated plates for a wide range of industrial and architectural applications. The stainless steel perforated plates we provide meet your needs in terms of design and functionality with their excellent corrosion resistance and strength.

Whether you need stainless steel perforated plates for screening, decoration, or protection, we can provide a variety of specifications and aperture options to meet different application requirements. Our products not only have competitive stainless steel perforated plate prices but also guarantee high-quality manufacturing processes and durability.

Please contact us directly to learn about the latest stainless steel perforated plate prices and get professional quotes and solutions.

Huaxiao Capacity about, stainless steel perforated plate,

Grade: 304 304L 304DQ 316 316L 201 202 301 310s 430 410s 409 409L 444 441 2205 2507, etc.

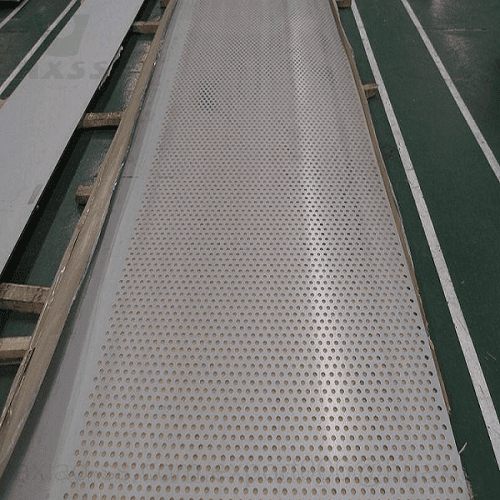

Thickness: 4.0mm – 10.0mm, We accept product customization.

Width: 100mm – 2000mm, We accept product customization.

Length: 500mm – 6000mm, We accept product customization.

Pallet weight: 1.0MT-10.0MT

Finish: NO.1, 2B, BA, 2BA, etc.

Hexagonal Hole Perforated Plates

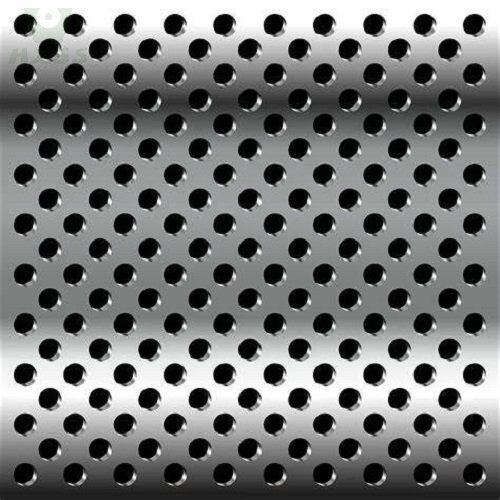

Sample of Perforated Stainless Steel Plate(4mm-10mm), Perforated Stainless Steel Mesh

Stainless steel perforated plate is a kind of metal mesh made by punching stainless steel plates in a CNC punching machine according to a set hole pattern. The plates are generally high-quality stainless steel plates such as SUS361, SUS304, and SUS201. The hole types have round holes, long round holes, square holes, triangular holes, scale holes, diamond holes, herringbone holes, long waist holes, plum blossom holes, I-shaped holes, and other special-shaped holes.

The biggest feature of a stainless steel perforated plate is that it has lightweight, has strong impact resistance, good filtering performance, a beautiful appearance, and a variety of patterns.

It is widely used in industry and is used for highways, railways, subways and other transportation through urban areas Environmental noise control barriers in facilities, sound-absorbing panels for sound insulation and noise reduction in building walls, generator rooms, factory buildings, and other noise sources, can also be used as sound-absorbing materials for building ceilings and wall panels.

Gorgeous speaker net covers, grinders, mine screens, I-shaped screens for grain, feed, mines, stainless steel fruit baskets, food covers, fruit plates, and other kitchen utensils for kitchen equipment, as well as shelf nets for shopping malls, decorative exhibition stands, and grain Ventilation and ventilation nets in the warehouse, and water filtration nets for football field lawns.

There are many types and specifications of stainless steel perforated plates. The perforated stainless steel mesh has good hardness and will not be damaged after a period of time. In addition, the stainless steel perforated plate is beautiful and generous. They are also used in many real-life applications, such as cement, environmental protection, decoration, etc.

Life will not be polluted. The size and thickness of the stainless steel perforated plate can be customized according to customer requirements. The products produced by Shanghai Huaxiao Metal Co., Ltd. are very complete. The stainless steel perforated plates produced by our company are of reliable quality and economical. Customers will do according to our requirements and serve them with 100% satisfaction and integrity. If you have any needs, please free to contact me. For more stainless steel products, please check our website.

The Production Process of Stainless Steel Perforated Plate:

1, First select the material of the perforated stainless steel mesh and accurately design the mold at the beginning of the punching plate/perforated stainless steel mesh. The quality of a die determines the quality of the perforated stainless steel mesh product in a large program, so we have been punching in recent years. The mold has invested a lot of money and energy, which has significantly improved the mold design and production capacity of our factory and accumulated some mold patterns.

Punching: Now it is produced by the most advanced wkc-2000 CNC punching equipment in China. Stepper motor feeding and plc operation control, the product accuracy reaches +/-0.15MM, and standardized management can be stamped in the range of 10mm–0.2mm.

2, the trimming of the board: If the edge of the manufacturing process exceeds the tolerance range you require, our skilled technicians can help you remove the excess edges according to your requirements;

3, the cutting of the board: cut from the entire roll of the board into the size you need;

4. Flattening of the perforated stainless steel mesh: We can use the leveling machine to restore the punched plate of the deformation to its original flat state.

Stainless Steel plates with a thickness of 0.8mm-12mm can be leveled. Cleaning the punching requires the use of lubricants, but we also have a degreasing process that removes traces from the surface and makes the orifice clean. Forming and deep processing, in addition to customer reservations, we can also provide a series of subsequent processing on the stainless steel perforated plate, including leveling, cutting, labeling, packaging, degreasing, deburring, forming, annealing, painting, electroplating, welding, Polishing, bending, rolling, etc.

Application of Stainless Steel Perforated Plate

1. Architecture and Decoration

- Facade Cladding: Used in building facades to provide a modern look while offering durability and wind resistance.

- Ceiling and Wall Panels: Applied indoors for decorative purposes, enhancing visual appeal and acoustic performance.

2. Industrial and Manufacturing

- Screening and Separation: Utilized in mining, chemical, and food processing industries for efficient material separation and filtration.

- Ventilation and Heat Dissipation: Employed in machinery, electronic devices, and HVAC systems to facilitate cooling and ventilation.

3. Safety and Protection

- Protective Covers and Barriers: Used to create protective covers and barriers, safeguarding equipment and personnel in industrial settings.

- Security Screens: Functions as security screens for windows and doors, combining strength and aesthetic value to enhance security.

4. Transportation

- Automotive and Aerospace: Applied in automotive and aerospace industries for heat dissipation and aesthetic components, enhancing both performance and appearance.

- Railway and Metro Facilities: Used in platforms and separation devices for durability and visual appeal.

5. Environmental Protection

- Water and Wastewater Treatment: Used in water and wastewater treatment systems for filtration and separation, ensuring water quality standards.

- Noise Control: Integrated into noise control systems to reduce noise pollution and improve environmental comfort.

6. Consumer Goods

- Home Furnishings: Featured in home decor and functional products such as grill racks, furniture accents, and kitchenware, adding both functionality and style.